You will find computer chips almost everywhere. In every car, you will find dozens of them, which aid in the temperature regulation of the engines and stabilization of the suspension systems. They are also helpful in managing internet cables, power lines, as well as water treatment plants.

In a nutshell, the modern world is incomplete without them. However, computer chips are not abundantly available. The ongoing global shortage leads to increased prices for the consumers and decreases profits for some big corporations in the United States. Here are a few things you need to know about the chip shortage, which is now very much a global problem.

What Is The Purpose Of A Semiconductor?

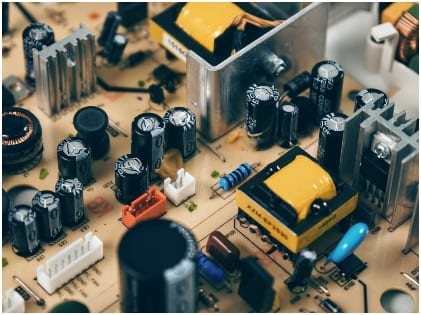

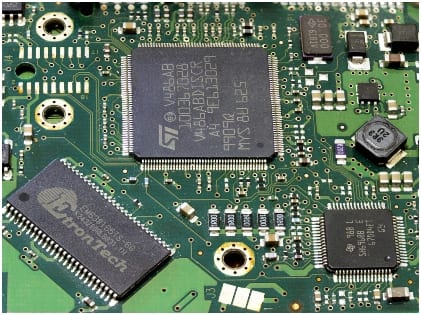

A semiconductor is also called an integrated circuit or a computer chip. It is a series of electric circuits that are embedded into silicon mainly. Silicon is a conducting material and thus helps in the purpose. For making computers and running any software, physical building blocks play a major role.

A semiconductor is also called an integrated circuit or a computer chip. It is a series of electric circuits that are embedded into silicon mainly. Silicon is a conducting material and thus helps in the purpose. For making computers and running any software, physical building blocks play a major role.

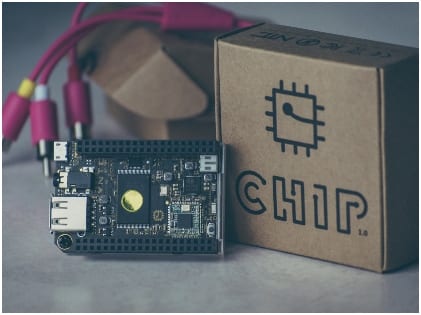

Semiconductors are necessary to form these blocks. Chip designers have been able to fit in more circuits into spaces that are much smaller in comparison, owing to the advancement of technology over the years. Therefore, they have made computers available at a much lower price and much faster than before. However, the complex design and the small size have been the reason behind the shortage you see today.

Why Aren’t More Chips Being Made?

Chips are not like toys or car engines. There are a lot of factors that count. The environments in which they manufacture semiconductors have to be kept safe from dust, temperature spikes, and static electricity. All these can prove lethal for the complex workings of integrated circuits or semiconductors. If companies are to meet the high or unexpected demand, they have to set up a different production line. And this implies that they have to hire more workers.

The controlled environments where they build these chips cost the company billions of dollars, and it takes around two years to set up a fully functional plant. Currently, the fabs are functioning quite well. But, if the extra demand is to be met, a new fab has to come up. That will take the company years to build. So, it’s not easy as it seems as a lot of factors go into consideration before proceeding.

Does The Pandemic Have Any Role To Play?

![]() COVID-19 pandemic has changed the definition of normal. And we are all busy embracing a life that has become the new normal. Aside from taking millions of lives in its grasp, it has also hit the world economy harder than anyone expected. It has damaged the supply chains and nullified any economic predictions that businesses had. Due to the pandemic, the prices of a multitude of products are now sky-high. Car manufacturing companies are under pressure to decrease production.

COVID-19 pandemic has changed the definition of normal. And we are all busy embracing a life that has become the new normal. Aside from taking millions of lives in its grasp, it has also hit the world economy harder than anyone expected. It has damaged the supply chains and nullified any economic predictions that businesses had. Due to the pandemic, the prices of a multitude of products are now sky-high. Car manufacturing companies are under pressure to decrease production.

People have lost their jobs, and therefore, their buying capacity has hit rock-bottom. As a result, purchasing non-essential goods have been cut off from their list. Those who are working are working from their homes. Hence, they have utilized the money they usually would have spent on holidays or movie tickets, on buying computers, videogames, and televisions.

The companies that manufacture electronic goods bought all the chips available and used them to fulfill the rising demand for electronic goods. By the time the car-manufacturing companies realized that people might still buy cars, it was late. Today, more than a million cars are in the factory’s parking, in their almost complete state. However, they cannot be up for sale without the chips.

Who Are The Worst Affected?

Consumers are paying the price. Since chips are an integral part, the prices for many products are now going up to such a level that they exceed the purchasing capacity of consumers. Some electronic goods are auctioned at twice their retail prices on eBay. In this situation, the consumers are losing out, and consequently, the manufacturers are not fruitful dividends on their investments. The companies now have to endure losses.

Consumers are paying the price. Since chips are an integral part, the prices for many products are now going up to such a level that they exceed the purchasing capacity of consumers. Some electronic goods are auctioned at twice their retail prices on eBay. In this situation, the consumers are losing out, and consequently, the manufacturers are not fruitful dividends on their investments. The companies now have to endure losses.

However, we can say nothing about how long this shortage would last. Demands wouldn’t suddenly come down sooner or later, especially as economic activity might accelerate in 2021. So, we need to wait and see how things pan out in the months ahead.